Single Screw Extrusion System

1.Motor of screw loader and feeder is controlled by inverter , and level sensor installed in the hopper makes the feeding speed adjusted automatically. 2.The plastic flakes will be mixed, melted and plasticized by the reliable single screw extruder. Double-zone vacuum degassing system ensures the high quality of the final product. 3.Two-stage extrusion system is available according to the condition of the raw materials. 4.Three different pelletizing systems are optional in condition of the MFI of the raw materials, die-face pelletizing system, strand pelletizing system and under-water pelletizing system. 5.Intelligent automatic modular control realizes the whole system one button start/ stop. Easy to operate, and protect the production line from wrong hand operation. 6.All electrical components are top brands: Siemens, Schneider, Omron, etc. Which ensures the system available for 24 hours working non-stop operation stably.

-

Hot

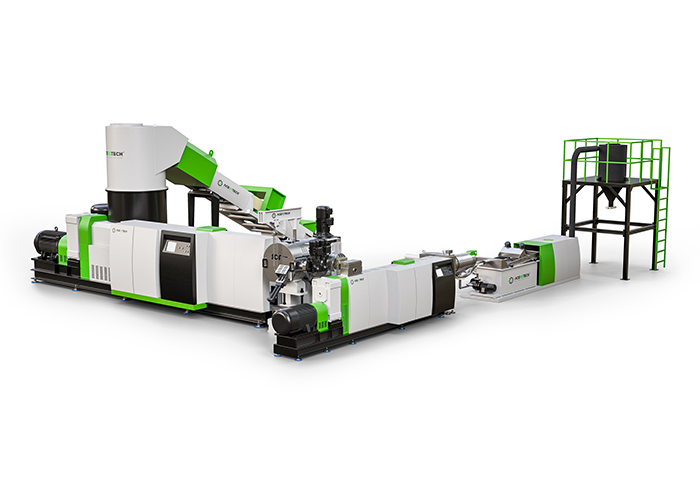

PP HDPE pipe flakes pelletizing line

AWTS PP HDPE pipe flakes pelletizing line combines quantitative feeding, high efficiency extruder, different types of filter and different types of pelletizer by modular design. It provides best solution for PE, PP, PS, ABS, PA and many other rigid plastic regrind recycling.

Email Details

AWTS series HDPE pipe flakes pelletizing line is one of the most popular recycling system in ACE WashTech. KSP PP PE flakes pelletizing line has started recycling pellets production in many country, such as Chile, Ukarine, Russia, India, etc. -

AWTS 80 Single Screw Extrusion System

1. Modular design, configuration can be adjusted according to the actual materials condition, especially suitable to materials in form of flakes, agglomerates,squeezed film, etc.

Email Details

2. Configure intelligence and controllable system, can realize the whole system start/stop automatically.

3. Longer processing length, optimized screw structure, to guarantee the final pellet's quality.

4. Lower energy consumption with high output.

5. Lower investment cost for a high quality and durable machine.

6. Fast machine delivery and installation. -

AWTS 100 Regrinding And Pelletizing System

1. Configure intelligence and controllable system, can realize the whole system start/stop automatically.

2. Modular design, configuration can be adjusted according to the actual materials condition, especially suitable to materials in form of flakes, agglomerates,squeezed film, etc.

3. Longer processing length, optimized screw structure, to guarantee the final pellet's quality.

4. Lower energy consumption with high output.

5. Lower investment cost for a high quality and durable machine.

6. Fast machine delivery and installation.extrusion device with single screw single screw extrusion machine rigid plastic materials evtrusion machineEmail Details -

Hot

AWTS 120 PP PE Flakes Extrusion And Pelletizing System

1. Longer processing length, optimized screw structure, to guarantee the final pellet's quality.

Email Details

2. Configure intelligence and controllable system, can realize the whole system start/stop automatically.

3. Modular design, configuration can be adjusted according to the actual materials condition, especially suitable to materials in form of flakes, agglomerates,squeezed film, etc.

4. Lower energy consumption with high output.

5. Lower investment cost for a high quality and durable machine.

6. Fast machine delivery and installation. -

AWTS 150 PP Scraps Extrusion And Pelletizing Line

1. Lower energy consumption with high output.

Email Details

2. Configure intelligence and controllable system, can realize the whole system start/stop automatically.

3. Modular design, configuration can be adjusted according to the actual materials condition, especially suitable to materials in form of flakes, agglomerates,squeezed film, etc.

4. Longer processing length, optimized screw structure, to guarantee the final pellet's quality.

5. Lower investment cost for a high quality and durable machine.

6. Fast machine delivery and installation. -

AWTS 180 Extrusion And Pelletizing System

1. Lower investment cost for a high quality and durable machine.

Email Details

2. Configure intelligence and controllable system, can realize the whole system start/stop automatically.

3. Modular design, configuration can be adjusted according to the actual materials condition, especially suitable to materials in form of flakes, agglomerates,squeezed film, etc.

4. Longer processing length, optimized screw structure, to guarantee the final pellet's quality.

5. Lower energy consumption with high output.

6. Fast machine delivery and installation. -

Hot

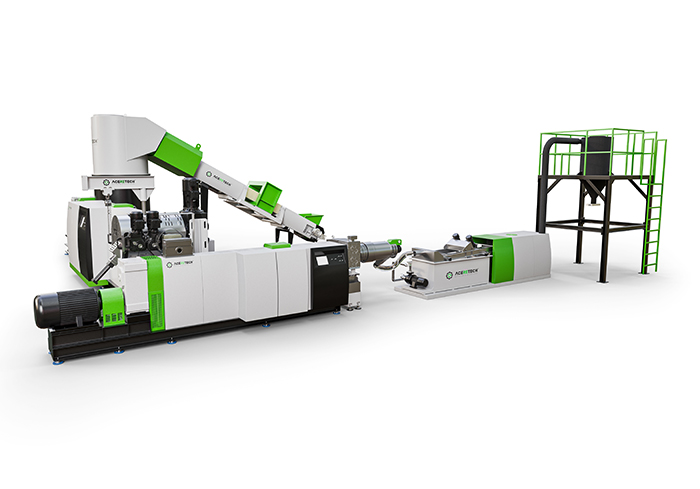

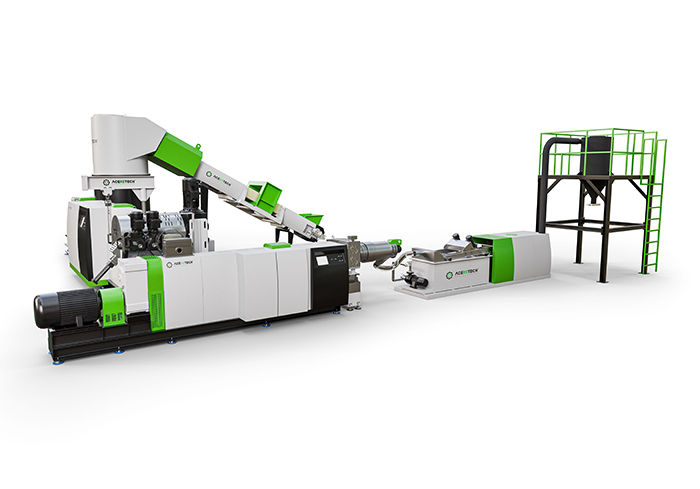

AWTS 100 120 Two-stage Extrusion And Pelletizing System

1. Lower investment cost for a high quality and durable machine.

Email Details

2. Fast machine delivery and installation.

3. Configure intelligence and controllable system, can realize the whole system start/stop automatically.

4. Modular design, configuration can be adjusted according to the actual materials condition, especially suitable to materials in form of flakes, agglomerates,squeezed film, etc.

5.Three kinds of pelletizing systems are optional to handle different type of rigid plastic scraps.

6. Longer processing length, optimized screw structure, to guarantee the final pellet's quality.

7. Lower energy consumption with high output. -

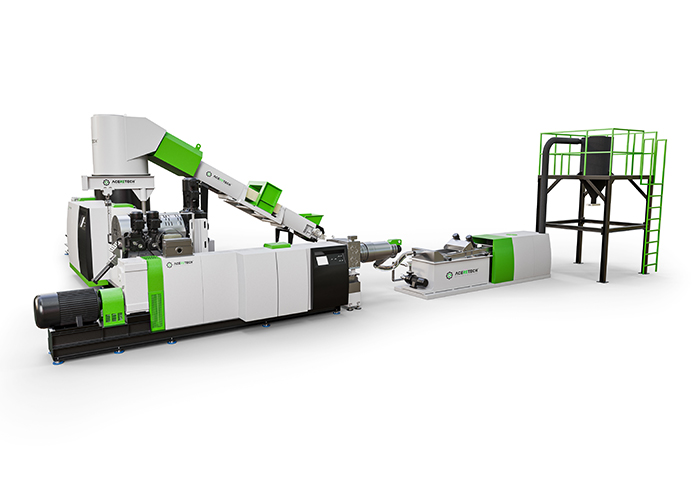

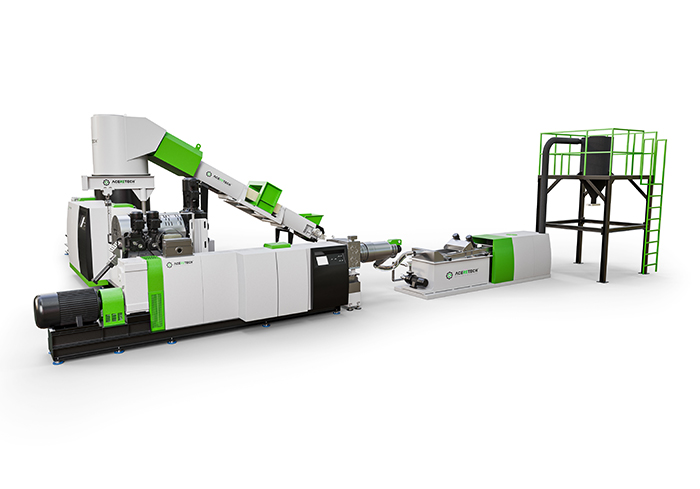

AWTS 120 150 Pelletizing Line With Two-stage Single Screw Extrusion

1. Configure intelligence and controllable system, can realize the whole system start/stop automatically.

Email Details

2. Modular design, configuration can be adjusted according to the actual materials condition, especially suitable to materials in form of flakes, agglomerates,squeezed film, etc.

3.Three kinds of pelletizing systems are optional to handle different type of rigid plastic scraps.

4. Longer processing length, optimized screw structure, to guarantee the final pellet's quality.

5. Lower energy consumption with high output.

6. Lower investment cost for a high quality and durable machine.

7. Fast machine delivery and installation. -

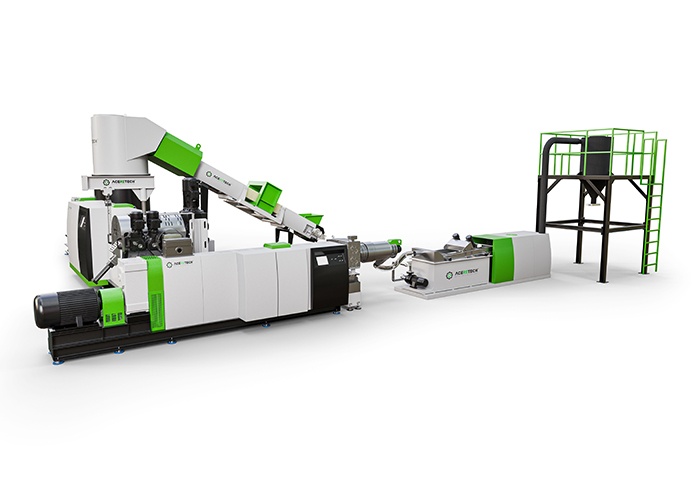

AWTS 120 150 Pelletizing Line With Two-stage Single Screw Extruder

1. Configure intelligence and controllable system, can realize the whole system start/stop automatically.

Email Details

2. Modular design, configuration can be adjusted according to the actual materials condition, especially suitable to materials in form of flakes, agglomerates,squeezed film, etc.

3.Three kinds of pelletizing systems are optional to handle different type of rigid plastic scraps.

4. Longer processing length, optimized screw structure, to guarantee the final pellet's quality.

5. Lower energy consumption with high output.

6. Lower investment cost for a high quality and durable machine.

7. Fast machine delivery and installation.