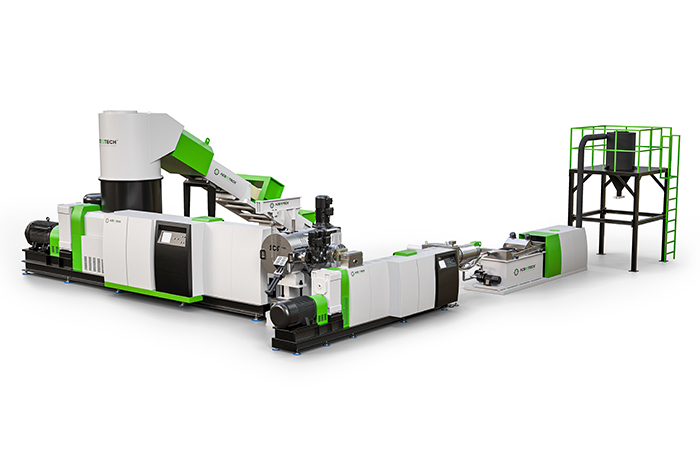

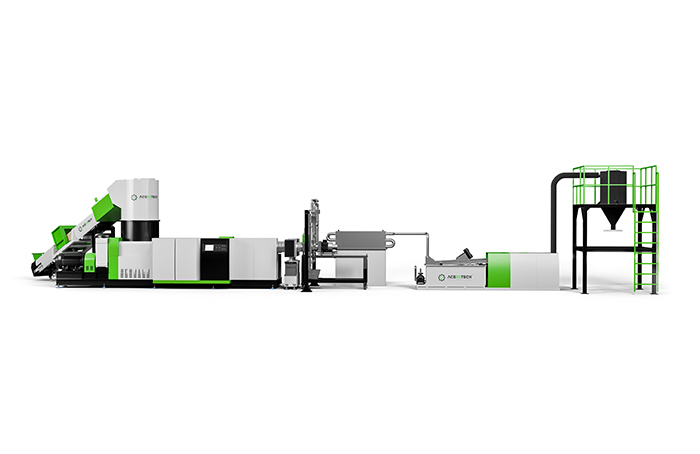

PP jumbo bags Compacting granulation system

- ACE WashTech

- China

- 45 days

- 100 sets

AWTech series PP jumbo bags Compacting granulation system is a three in one recycling machine designed for low density plastic articles. It could provide the excellent re-pelletizing solution for film, raffia, filament, woven bag and nonwoven fabric which sourced from production factory and washing line.

KCP series PP jumbo bags Compacting granulation system has a wide application in PE film recycling, PP big bag recycling, CPP, BOPP, PS, PPS, EPS, ABS, PA, PLA, PET materials recycling field.

AWTech series is one of the most popular recycling system in ACE WashTech. AWTech PP PE film compacting and pelletizing line has created good benefits for customers in Germany, Canada, Brasil, Chile, Dominica Republic, Vietnam, Russia, Nigeria, Serbia, Iran.

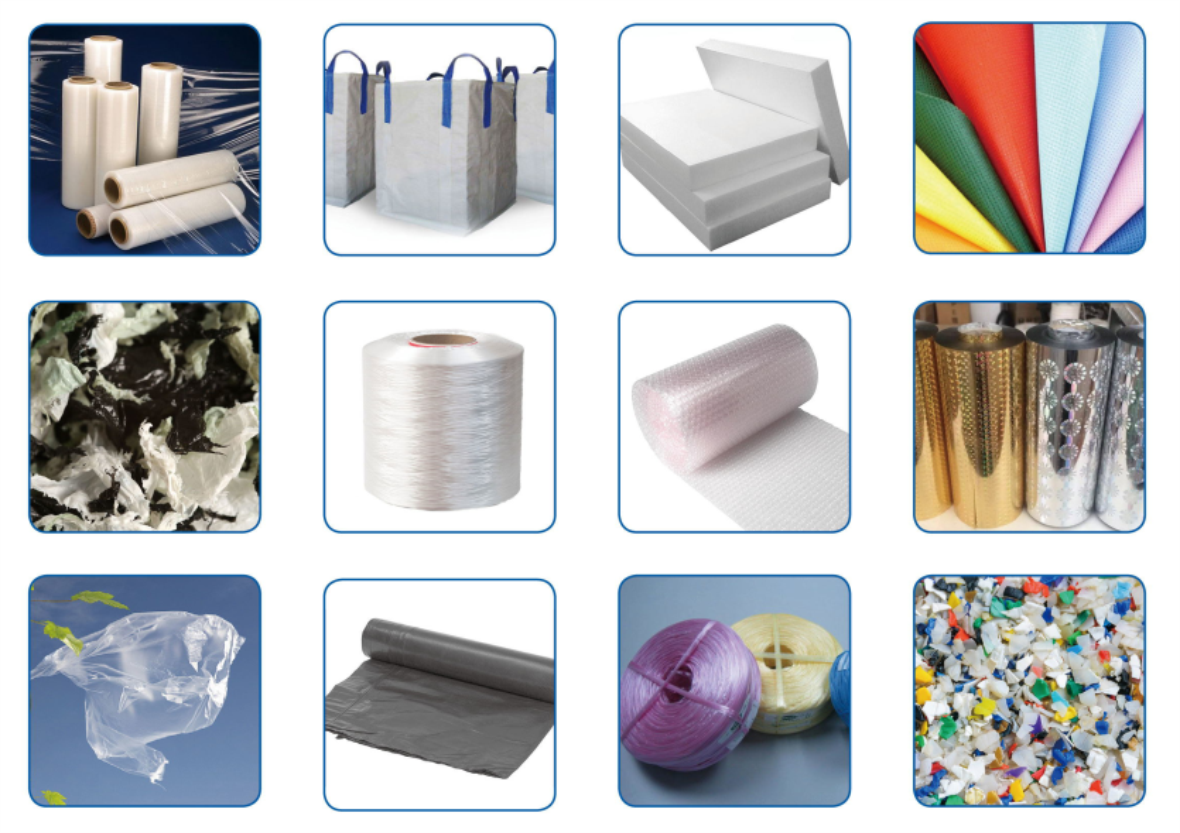

Raw material

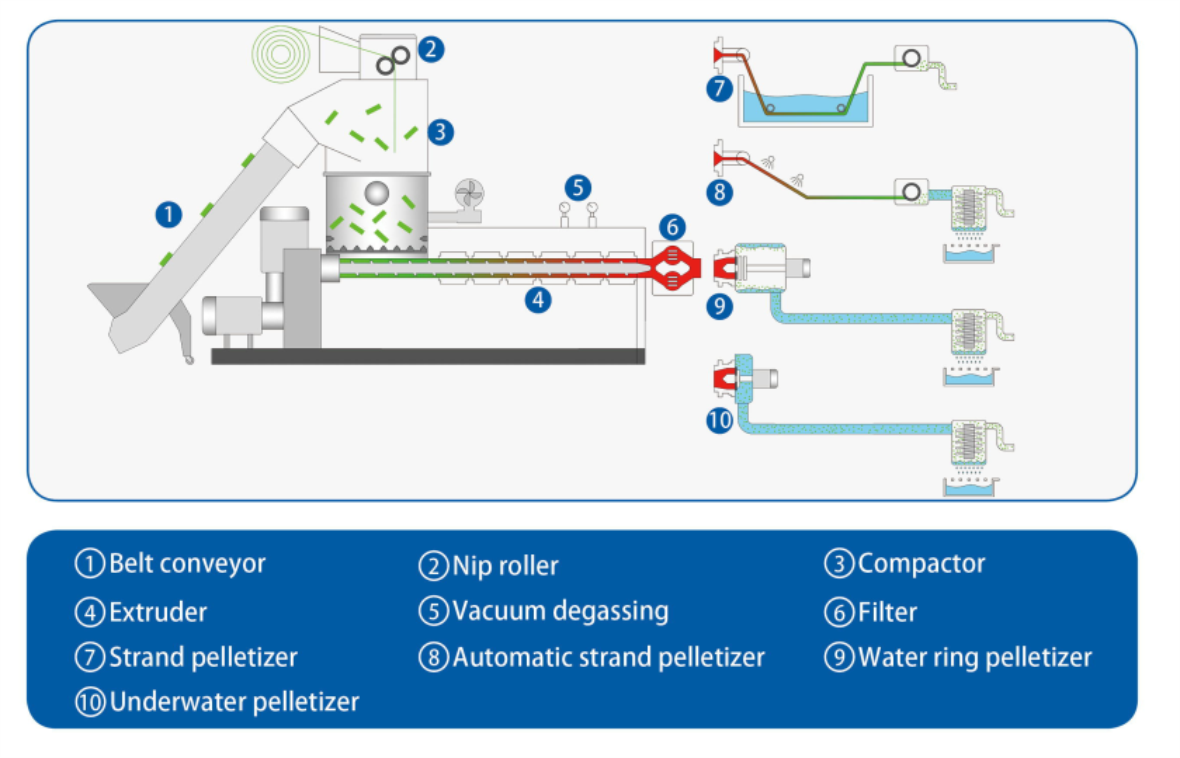

Flow chart

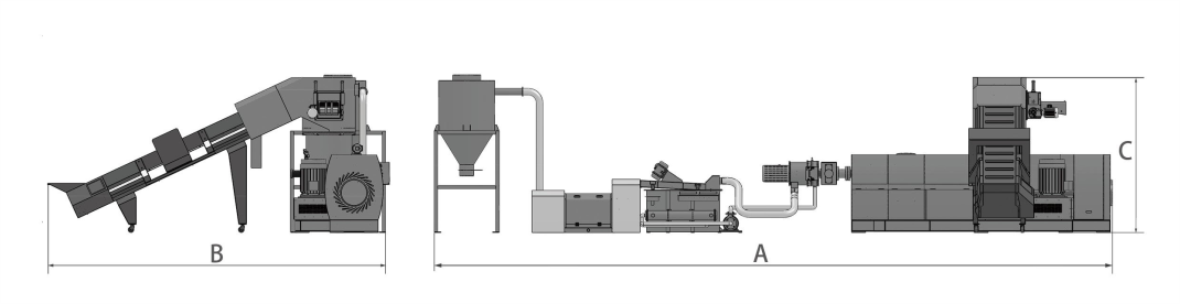

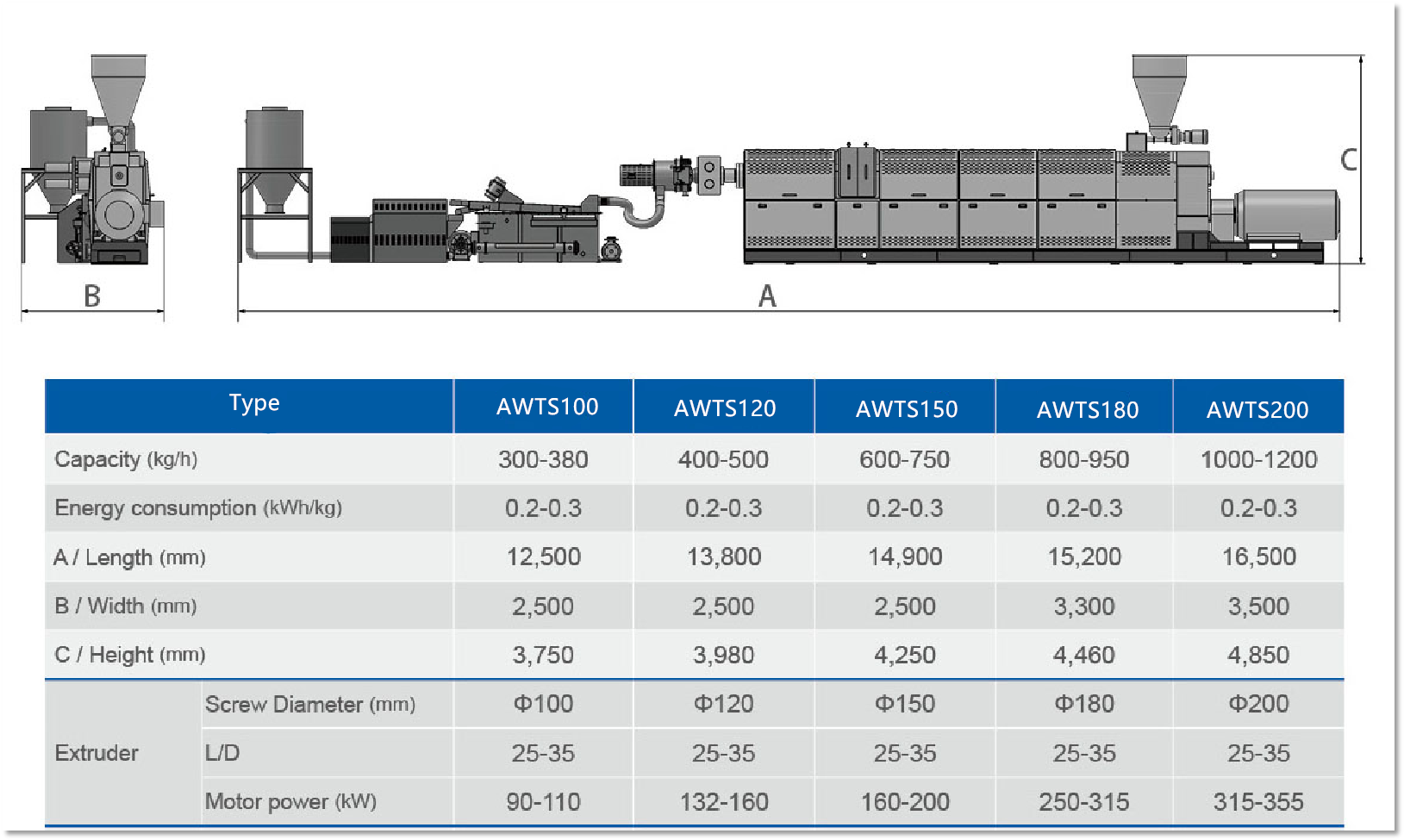

Technical specification

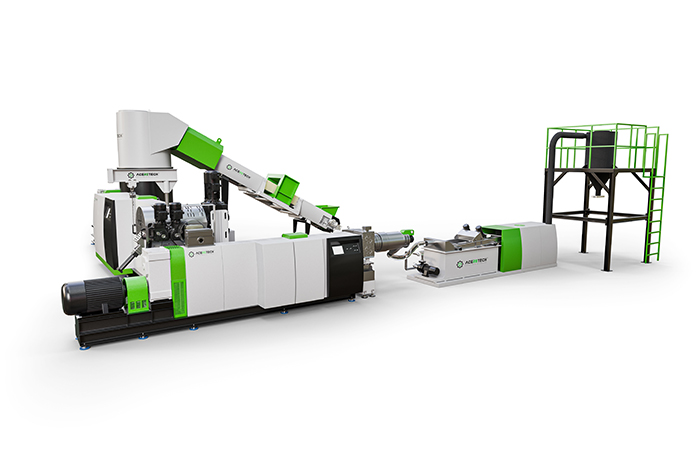

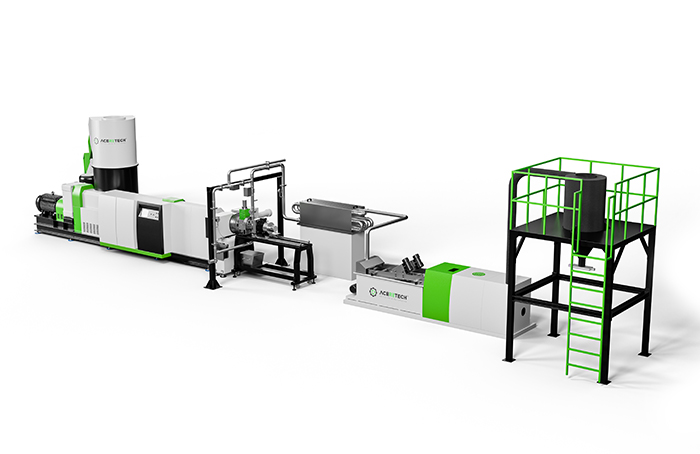

Feeding and compacting unit

Belt conveyor as well as screw conveyor and NIP roller, optional feeding method designed for different type of material.

Ferrous and nonferrous metal detecting and separating, to protect the compactor effectively

Sliding gate designed for compactor to control the feeding amount into extruder automatically, make ensure the extruder run steady.

The material got cutting, mixing and compacting in the compactor uniformly, to ensure the material heated and effectively.

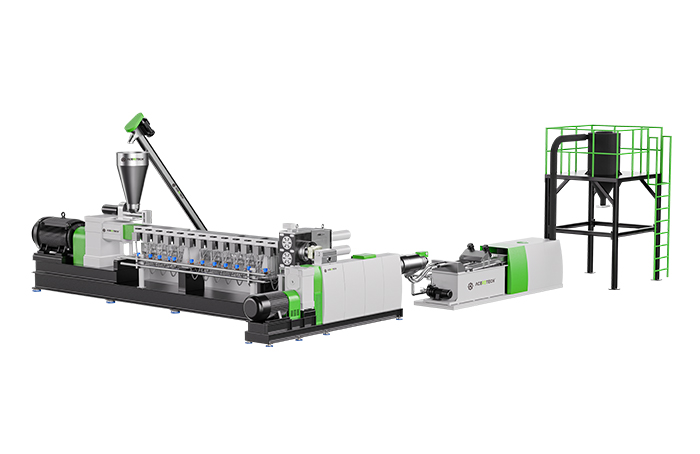

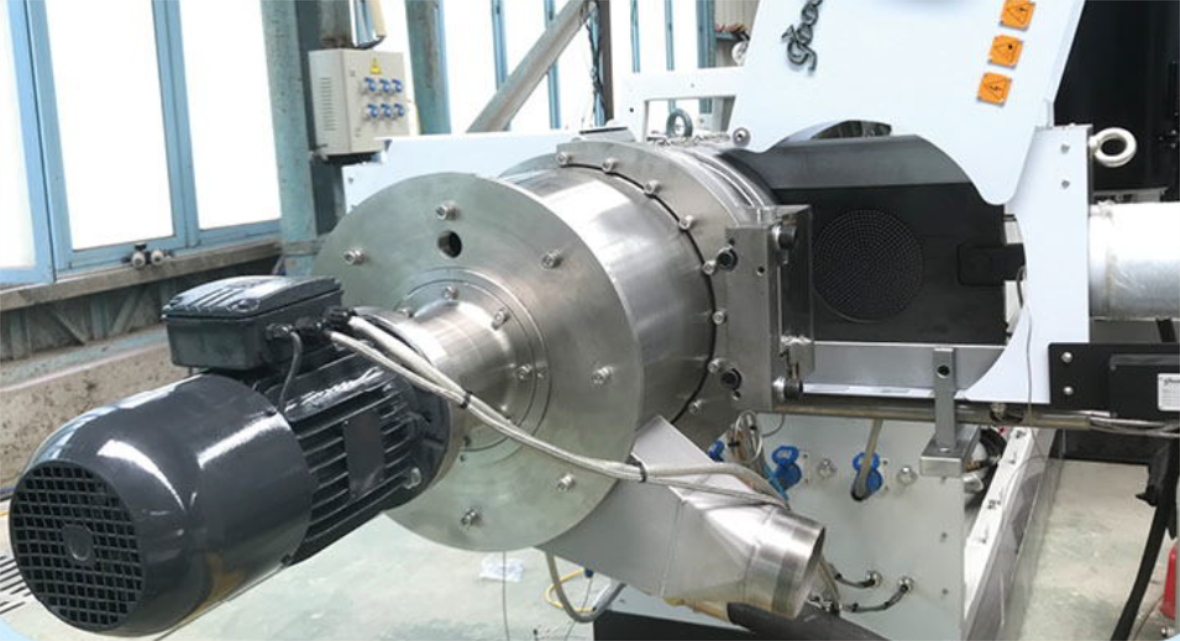

Extrusion unit

High efficiency barrel and screw used for extruder with excellent plasticizing result and high output capacity. Adopt high wear resistant alloy material to ensure 1.5 times service life of normal one.

Force double vacuum degassing system to get rid of the low molecular, moisture and printing ink effectively, make sure high quality output pellets.

High efficiency infrared heater can heat rapidly with continuous thermal insulation, more than 30% energy consumption can be saved than normal heater.

Diversified L/D ratio optional for different application. Multi-vacuum degassing system and double stage extrusion system help you solve the problem of recycling heavy contaminated polymer.

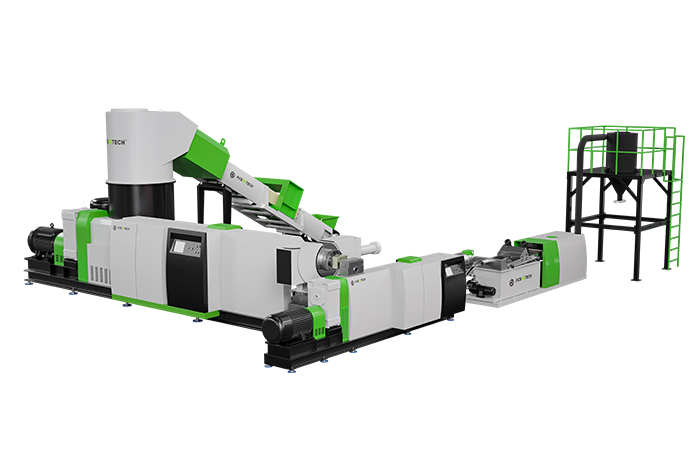

Filtration unit

Plate type, piston type, back flush type and automatic self-cleaning type filter, you have different choice according to impurity contents in material and your habit.

Plate type filter is cost-effective and easy to operate which mainly used for regular thermoplastic as usual filtration solution.

Large area filter can be used to ensure the filtration effect. Minimize the impurity content in the filtered melt and improve the quality of final pellets product.

Pelletizing unit

Water ring pelletizer, strand type pelletizer, automatic strand type pelletizer, automatics strand pelletizer and under water pelletizer, ACE WashTech provides four different pelletizing solutions for you aiming at different MFI polymer will get different shape output pellets.

The uniformity, gloss and properties of final pellets can be ensured for either pelletizing solution.

Intelligent control unit

Thanks for Siemens PLC and HMI, LCP series machine provides high intelligent operation system which is easy to operate and save man power.

PLC intelligent control system avaliable for remote diagnosis, control and monitoring to ensure that all user's systems can be updated and maintained and operated for a long term.

Weighing and metering system helps you monitor the output and energy consumption of production line in real time under different materials and production conditions.

All data can be connected to ERP system for quantitative assessment.