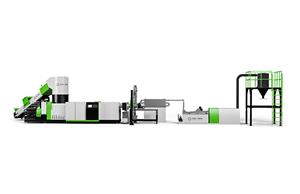

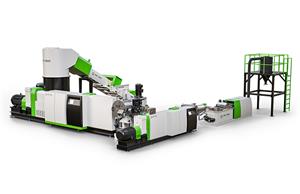

Buy ABS agglomerates recycling and pelletizing system Price

ABS agglomerates recycling and pelletizing system

One of the main ways to expand your 3D printing capabilities is to learn how to print 3D molds. We're not talking about microbiology, we're creating containers to fill your mind. They are great for mass production, standardizing your designs and expanding your tracks that you can do for yourself. Here, we'll give you a brief overview of what 3D printed stencils are, how to create and use them, and why they are a good idea.

First, we need to distinguish between two types of object creation to show how printing 3D stencils differ from your standard 3D print project. The main difference is how to get the final object.

Standard 3D printing is a means to an end - once your printer stops working and your material cools down, you get your final product. The standard 3D printing process is additional, which means you shape your shape when you print. When the material is squeezed, your design is in place, and that's how you're done.

3D printing molds requires an additional step. First, print a container that is the opposite of the final design, and then you fill the container with the final manufacturing material, let it dry, and then open the mold to reveal the final object. We'll go into more detail below, but for now, as long as you know that these general steps are called addition manufacturing, you do need to do a little more work than a standard 3D printing project. But we promise it's definitely worth it.

The chief executive of Mid Valley Disposal Said he had 3,000 tonnes of paper piled up, up from about 500 tons a few years ago. The problem boils down to one thing, reducing the need for recyclable content.

"There's no way out of it," he said. "There is an oversupply in the market. "

His company serves Sanger and 27 other cities, including about half of Fresno's business. When his company finds a buyer, the price paid is only a fraction of what it used to be.

Buy ABS recycling system

The culprit is not a man. But an important participant is China, which changed its acceptance rules in January 2018 and significantly reduced imports. The Washington Post's Rebecca Beitsch reported earlier this year that China's move will affect rural and small townspeople more than big cities with the financial resources to better protect their populations.

Falling prices and demand for recycled plastic, paper and metal are not a good time for California. California aims to recycle 75 percent of its waste statewide by 2020. CalRecycle, the state agency that oversees the work, said 23 million tons would be needed to "recycle, reduce or compost" 23 million tons to achieve that goal. The agency estimates that California will produce about 80 million tons of solid waste next year.

'Unfortunately, since the shift in the Chinese-influenced market, the conversion rate of garbage bins across the country has been declining, from about 52 percent to about 41 percent, ' Mr. Karpakov said.

This puts recyclers in a difficult position.

Mr. Karpakov says his company has weathered the crisis better than some. In 2014, Mid Valley Processing acquired Sunset Waste and its 12-year-old recycling sorting system. Two years later, Mid Valley designed a completely new system and installed it in 2017. The improved facility handles 35 tons of recycled waste per hour, compared with 15 tons per hour in the previous system.

The new system has an optical sorter that can identify different grades of plastic, polyphenyl glycol (PET), and high density polyethylene (HDPE).

However, despite their high efficiency, size and complex structure, these machines cannot do all the work. Staff need to separate all contaminants, a range of pollutants used in long and complex distribution machines and conveyor belt networks.

agglomerates recycling and pelletizing system Price

The process begins with a large loader, mounts wide tires with no tread pattern, and pours one barrel after another into the first. From there, the materials were transported to a pick-up line made up of fast-moving workers, which Karpakov called his a team. These skilled workers pulled out the rubbish that should not have been put in the recycling bin.

Kalpakov stood by as workers carried out green trash, tarpaulins, sofa cushions, a large baby car seat, garbage bags, car parts and all sorts of debris that could clog the next sorter and cause costly delays.

Herbold crushing machines grind all types of plastic waste, and it doesn't really care that it comes from injection or blow molding, thermoforming, rotomoulding, flat extrusion or blow molding film extrusion, pressing or squandering production of pipes, profiles and plates or from other plastic products. For example, Herbold's patented SB-type forced granulation machine (SB-type forced granulation granulation machine) has been operating successfully worldwide for many years. The material was not fed.