Buy Low price PET bottle pelletizer granulator machines Factory

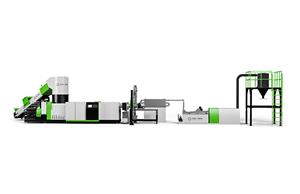

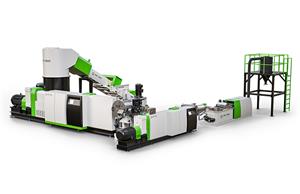

PET bottle pelletizer granulator machines

Manufacturers of food and other packaging-intensive products require large quantities of uniform reusable plastic particles/sheets. Herbold Meckesheim USA, Smithfield, Rhode Island, said in a press release that when the hot cleaning system was integrated into a new or existing plastic recycling line, it came from Smithfield, Rhode Island. Smithfield's Herbold Meckesheim USA systems can help processing plants meet this demand.

Herbold Meckheim, Inc. is a subsidiary of Herbold Meckheim, Germany, which designs, manufactures and installs dediameteration equipment and production line systems for the plastics industry. The company's Herbold thermal cleaning system was originally designed for polyphenyl glycol (PET) bottles and can also be used in a variety of other projects, including thermoformed foils, trays and foils for the packaging industry.

Fat impurities in emulsion, cooking oil, or sunscreen residues are dissolved and washed away, as are residues of labels and adhesives, according to a press release from Herbold Meckheim. At the front end of the process, the elimination of impurities results in larger, essentially clean, available scales. This method of improving the cleanliness of the flakes is proven by significantly reducing the particles found in the squeeze melt filter - usually 50% less than the non-hot-washed flakes. The resulting clean scales also reduce odor, completely transparent and non-yellow.

The Hubbold thermal cleaning system is custom configured to best suit the application's need slot slots of various components, which may include multi-chamber separation tanks, friction washers, turbo washers, mechanical or hot air dryers.

Typically, the system is used online as part of a continuous process. However, when cleaning is the most important time, the hot cleaning process can be performed offline, allowing users to adjust the dwell time of the mixing tank to reach the desired level of cleaning, the company said in a press release.

Buy PET bottle pelletizer granulator machines

At the 14th Meeting of the Parties to the Basel Convention, Governments voted in favour of restricting the export of plastic waste, requiring countries to obtain prior informed consent before exporting contaminated or mixed plastic waste. According to the proposal from Norway, the summary is available, and the revision of the Basel Convention signed to control the transboundary movement of hazardous waste is intended to "clean up international trade in plastic waste" and to help reduce the leakage of plastics into the marine environment and communities.

"Clean" plastic "waste" has been classified according to specifications prior to export and is suitable for immediate recycling, with minimal further mechanical procedures;

"other" plastic waste, including mixed plastic or other waste, or contaminated and subject to the Basel Convention control system;

"Dangerous" plastic waste, contaminated with (Annex I) components, with (Annex III) hazardous characteristics, and subject to the Basel Convention.

According to the World Wildlife Fund (WWF), a mixture of polyethylene (PE), polypropylene (PP) and polyethylene glycol (PET) will not be subject to consent conditions.

The United States is one of only two countries that have not ratified the Basel Convention. However, the U.S. Environmental Protection Agency says the treaty still affects U.S. importers and exporters. Parties to the Basel Convention cannot trade sites with non-parties for waste covered without prior-determined agreements between countries.

Invema now produces about 4.4 million pounds of washed pet flakes per month, Gatlin told Plastic Recycling Update at the end of April. About 1.3 million pounds will be recycled into food-grade balls and 1.2 million pounds will be recycled into food-grade flakes. The remaining flakes will be put on the market.

Low price pet bottle granulator Factory

Invema is currently getting approval to sell micropills to major beverage brands, including Coca-Cola, Gatlin said. They hope to get approval around July. Invema is sending samples from the production line to a variety of thermoforming customers, mainly in the United States

Currently, he says, the company sells sheets that have been cleaned in Herbold systems, mainly in the U.S. to the rPET resin, sheet, fiber and strapping industries.

Herbold, a German company, issued a press release about the device, stating that recycled consumer plastics produced by Invema meet U.S. Food and Drug Administration (fda) standards. The press release provides a basic description of Herbold's equipment flow: PET bottles are pre-selected before being reduced in two Hebold granulators( each with a production capacity of 1800 kg per hour). The flakes are then washed cold and hot, dried and sent to the thin sheet sorting device.