Buy Sales plastic profile extrusion plant machine line Quotes

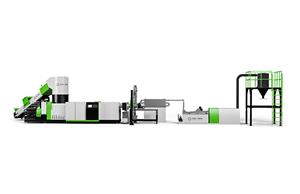

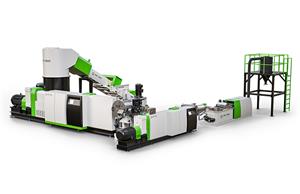

plastic profile extrusion plant machine line

Sales plastic extrusion plant

These packages are made under the Hilex Poly brand and are sold to all grocery stores and retail outlets in the mid-Atlantic and Southeast, sometimes across the country. The company declined to provide the names of its customers.

Shoppers can determine whether the bag is made at the Henrico plant by looking at the number "375" printed on the bag.

The factory employs 112 people 24 hours a day, 7 days a week. The company, which has been producing plastic bags since 1993, was acquired by Novolex in 2005 after its predecessor, Vanguard Plastics.

Novolex's revenue in 2017 was about $2.4 billion, according to the latest data from Forbes magazine. Novolex was ranked 193rd on last year's list.

In the mid-1990s and early 2000s, Henrico's plant underwent two expansions, adding 40,000 square feet of warehouse space and additional conversion lines and extrusion equipment.

The demand for plastic bags is on the rise during the holiday shopping season, but local factories are operating at full capacity almost all year round, Selby said.

"At its peak, we couldn't produce enough food, " he said. "In the valley, that's when we built it. "

As the economy as a whole grows, demand remains strong, despite pressure on businesses to reduce the use of plastic bags. Some state and local governments have banned the use of plastic bags or charged for their use because of concerns about the environmental impact of plastic bag waste.

plastic extrusion line Quotes

In March, for example, New York lawmakers passed a ban on the use of single-use plastic bags in retail, and California passed similar restrictions in 2016. Oregon lawmakers also recently passed a bill banning single-use plastic bags.

The ban is not absolute. New York, for example, has exceptions, such as allowing the use of plastic bags in deli sales, prescription drugs or bulk sales. New York state counties can also choose to charge 5 cents for paper bags, a move designed to encourage people to reuse plastic bags while shopping.

Novolex executives stressed that recycling is a solution, noting that the Henrico plant is a good example of how recycling can be integrated into the supply chain.

The company not only makes plastic bags. With 60 plants in North America and Europe, it manufactures more than a dozen brands of bags and packaging, including paper bags.

Novolex's vice president of public affairs and former senior director of sustainability, Phil. We also make paper bags from recyclable materials. "

"The architecture we build as a company is that we focus on choice, sustainability and innovation," says Mr Rozansky. "We want people to have a choice. If people use plastic bags, we want to use recyclable materials. "

Miraclone said in a July 2 statement that deals related to Mexico and India were expected to follow in the third quarter.

The new U.S. owner will move Uniloy's blow molding machine manufacturing business from its Afton plant in Miraklen, Ohio, to Uniloy's global headquarters in Tecumse, Michigan. , will join Uniloy's mold manufacturing business.

In Europe, Magenta and Italy's facilities will serve as European technology centres, in Latin America Uniloy will continue to operate a technology center in Queretaro, Mexico, and in Asia, Uniloy will continue to sell blow molding machinery made in India.

Buy plastic profile extrusion machine

Industry veteran Brian Marston will serve as Uniloy's president and chief executive. Marston has held leadership positions in the plastics and blow molding industry for more than 35 years and most recently served as President of The Mirakran Blow molding and extrusion. In addition to Marston, Uniloy's management team includes Chris Peters, Vice President of Finance, and Tom McDonald, Vice President of Operations.

Cincinnati, Ohio-based Milacron announced the sale of its Uniloy business in mid-May, just two weeks after it disclosed in its first-quarter financial report that it would exit the Uniloy business and put it up for sale.

Miraclone from Johnson Controls Inc. in 1998 Buy Uniloy. Milacron plans to retain the structured foam business it acquired from Johnson Controls at the same time.

The device precisely cuts polyolefins and PVC pipes to meet customer requirements, is fast and chips-free, and does not use hydraulics. In addition, the weight of the saw frame is reduced by 60 percent compared to conventional systems, which is a considerable advantage when the blade length is less than 50 cm, Stieglitz said. Acceleration and deceleration times have also improved significantly.

The tool is powered by a linear actuator, reducing the number of components, reducing maintenance requirements while improving accuracy and flexibility, Bad Oeynhausen of Germany said in a press release.