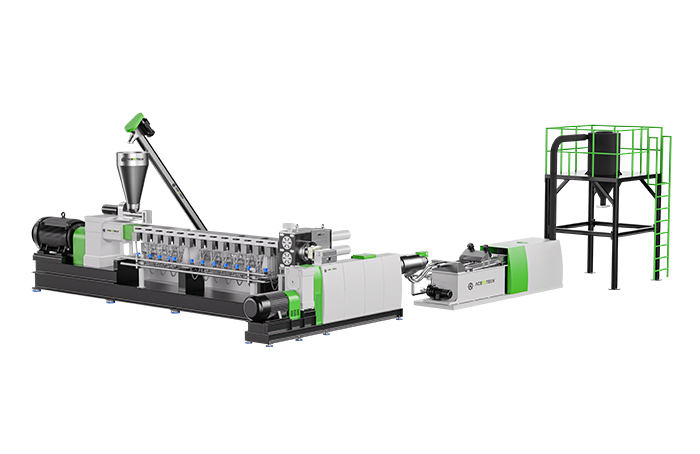

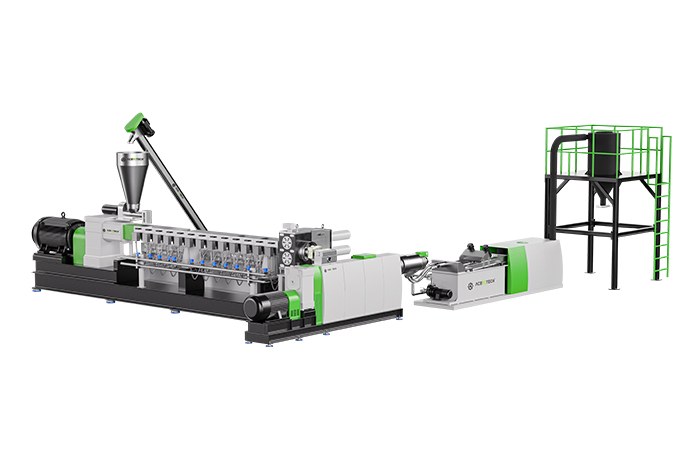

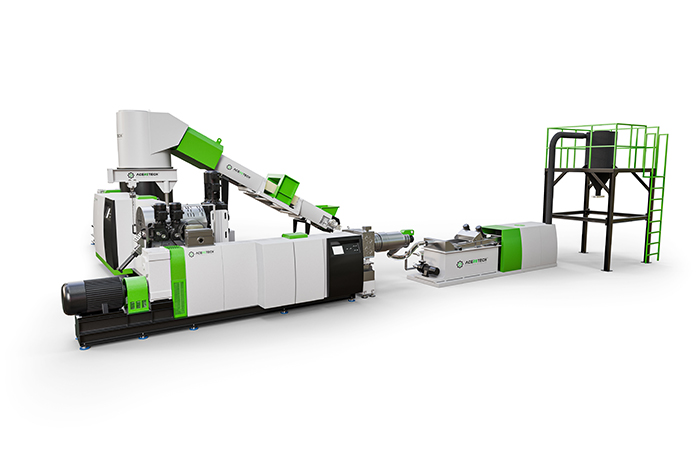

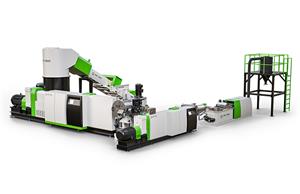

PE PP Film Compacting And Pelletizing System

1.Combine crushing, compacting and pelletizing steps in one system, less labor cost. 2.High torque gearbox with low speed ensures more than 5000 hours reliable running, and less than 0.1% oil leakage. 3.Single screw with double-zone vacuum degassing system especially suitable to heavy printed film and material with water content max 8%. 4.Water-ring pelletizing system applied to recycling materials like PP/ PE film.,BOPP, HIPS. It is a special pelletizing device with unique design and Higher MFI. 5.Control system used Siemens PLC, Omron, Schneider and other famous brands electrical components. It makes the machine performance more stable and easy to operate.

-

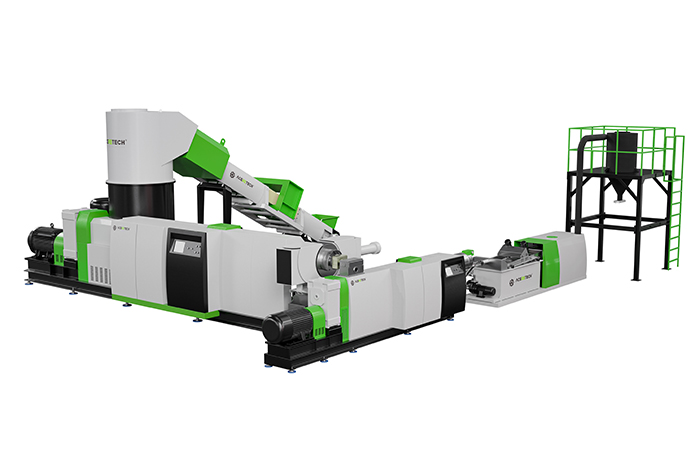

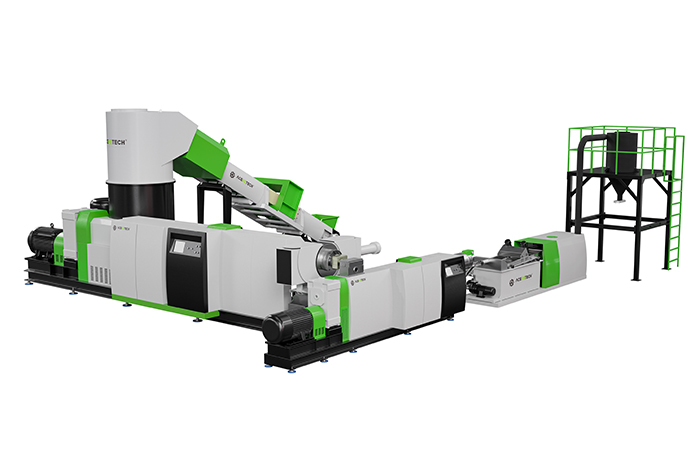

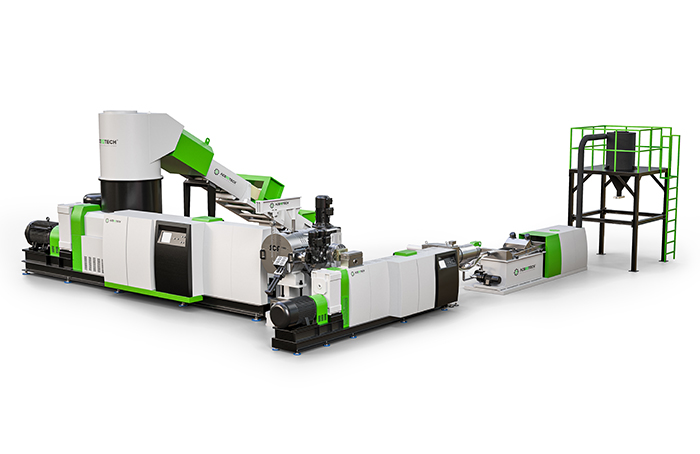

BOPP Extrusion And Strand Pelletizing System

1. AWTech series provide best solution for PP PE film,raffia, filament, bang, woven bag, nonwoven fabric and EPS foam material recycling.

Email Details

2. Compactor make material crushed, dried and compacted in one step.

3. Double-zone vacuum degassing system with efficient air exhausting to remove volatile.

4. Cutting speed controlled by PLC automatically according to the melt pressure to get uniform granules.

5. Seimens PLC with intelligence control HMI. One button to start-up and one button to stop whole system.

6. All electrical units: Seimens, ABS and LS. -

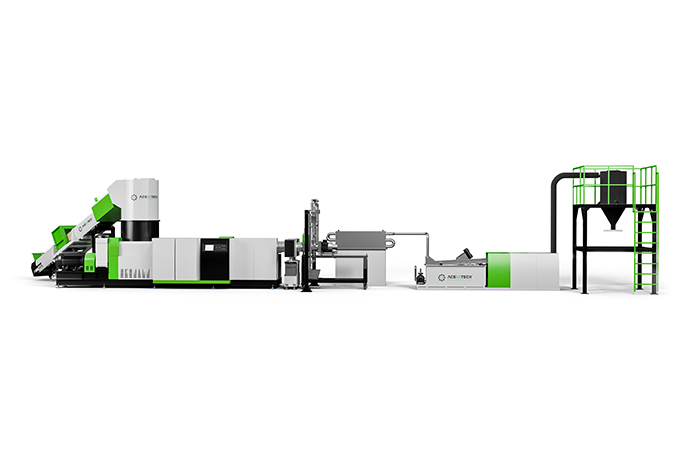

PE Strand Pelletizing Line

1. Configure intelligence and controllable system, can realize the whole system start/stop automatically.

Email Details

2. Modular design, configuration can be adjusted according to the actual materials condition, especially suitable to materials in form of film, bag, tape, etc.

3. Longer processing length, optimized screw structure, to guarantee the final pellet's quality.

4. Higher output and lower energy consumption.

5. Lower investment cost for a high quality and durable machine.

6. Fast machine delivery and installation. -

Compacting And Extrusion System With Cold Strand Cutter

1. Configure intelligence and controllable system, can realize the whole system start/stop automatically.

2. Modular design, configuration can be adjusted according to the actual materials condition, especially suitable to materials in form of film, bag, tape, etc.

3. Longer processing length, optimized screw structure, to guarantee the final pellet's quality.

4. Higher output and lower energy consumption.

5. Lower investment cost for a high quality and durable machine.

6. Fast machine delivery and installation.compacting and cold strand pelletizing system pelletizing line with cold strand cutter cold strand cutting wayEmail Details -

ABS Extrusion And Strand Cutter System

1. AWTech series provide best solution for PP PE film,raffia, filament, bang, woven bag, nonwoven fabric and EPS foam material recycling.

Email Details

2. Compactor make material crushed, dried and compacted in one step.

3. Double-zone vacuum degassing system with efficient air exhausting to remove volatile.

4. Cutting speed controlled by PLC automatically according to the melt pressure to get uniform granules.

5. Seimens PLC with intelligence control HMI. One button to start-up and one button to stop whole system.

6. All electrical units: Seimens, ABS and LS. -

PC Extrusion System With Cold Strand Cutter

1. Configure intelligence and controllable system, can realize the whole system start/stop automatically.

Email Details

2. Modular design, configuration can be adjusted according to the actual materials condition, especially suitable to materials in form of film, bag, tape, etc.

3. Longer processing length, optimized screw structure, to guarantee the final pellet's quality.

4. Higher output and lower energy consumption.

5. Lower investment cost for a high quality and durable machine.

6. Fast machine delivery and installation. -

PVC Extruder And Strand Cutter

1. AWTech series provide best solution for PP PE film,raffia, filament, bang, woven bag, nonwoven fabric and EPS foam material recycling.

2. Compactor make material crushed, dried and compacted in one step.

3. Double-zone vacuum degassing system with efficient air exhausting to remove volatile.

4. Cutting speed controlled by PLC automatically according to the melt pressure to get uniform granules.

5. Seimens PLC with intelligence control HMI. One button to start-up and one button to stop whole system.

6. All electrical units: Seimens, ABS and LS.PVC recycling line extrusion and cold strand pelletizing line for PVC recycling PVC strand cutting machinesEmail Details -

Compactor And Under-water Pelletizing Line

1. AWTech series provide best solution for PP PE film,raffia, filament, bang, woven bag, nonwoven fabric and EPS foam material recycling.

2. Compactor make material crushed, dried and compacted in one step.

3. Double-zone vacuum degassing system with efficient air exhausting to remove volatile.

4. Cutting speed controlled by PLC automatically according to the melt pressure to get uniform granules.

5. Seimens PLC with intelligence control HMI. One button to start-up and one button to stop whole system.

6. All electrical units: Seimens, ABS and LS.Compacting with under-water pelletizing line under-water pelletizing system with compactor compacting and under-water pelletizing systemEmail Details -

PP Yarn Compacting And Pelletizing System

1. Configure intelligence and controllable system, can realize the whole system start/stop automatically.

2. Modular design, configuration can be adjusted according to the actual materials condition, especially suitable to materials in form of film, bag, tape, etc.

3. Longer processing length, optimized screw structure, to guarantee the final pellet's quality.

4. Higher output and lower energy consumption.

5. Lower investment cost for a high quality and durable machine.

6. Fast machine delivery and installation.solution for recycling PP Yarn PP yarn compacting and pelletizing system compacting and under-water pelletizing systemfor PP YarnEmail Details -

Under-water Pelletizing System For ABS

1. Compactor make material crushed, dried and compacted in one step.

Email Details

2. AWTech series provide best solution for PP PE film,raffia, filament, bang, woven bag, nonwoven fabric and EPS foam material recycling.

3. Double-zone vacuum degassing system with efficient air exhausting to remove volatile.

4. Cutting speed controlled by PLC automatically according to the melt pressure to get uniform granules.

5. All electrical units: Seimens, ABS and LS.

6. Seimens PLC with intelligence control HMI. One button to start-up and one button to stop whole system.