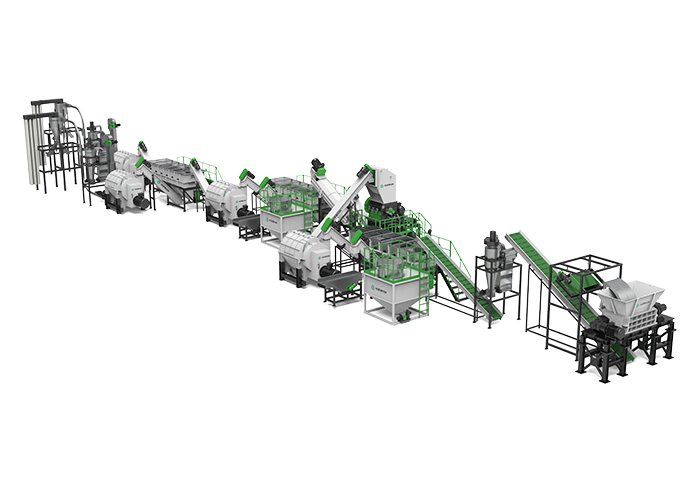

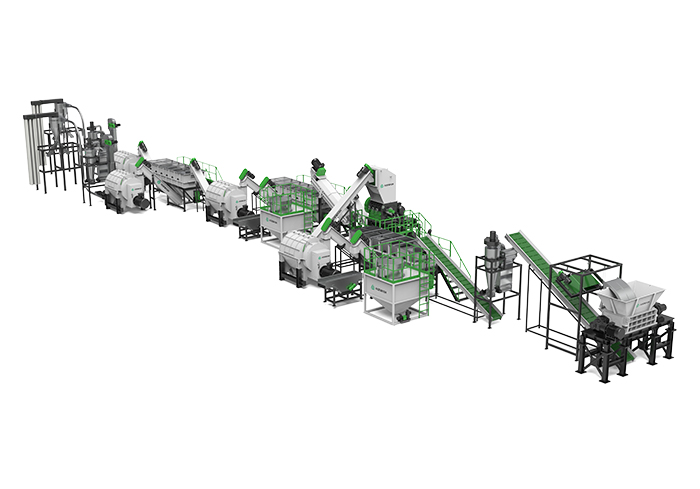

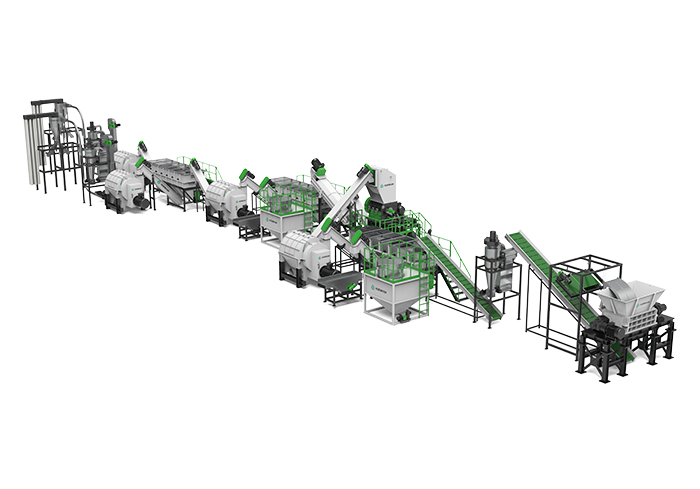

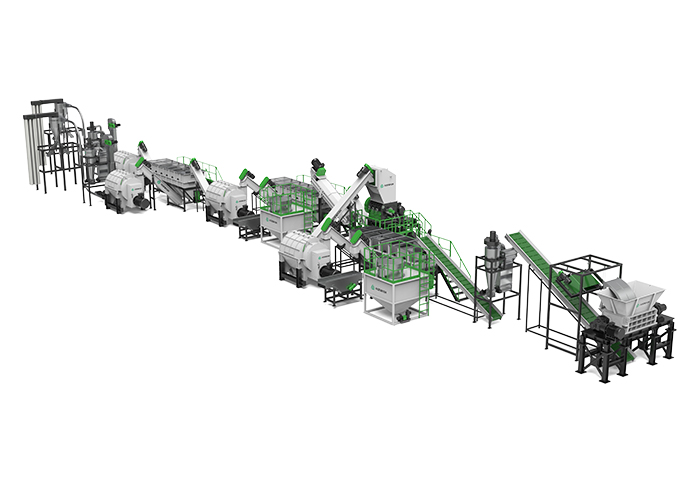

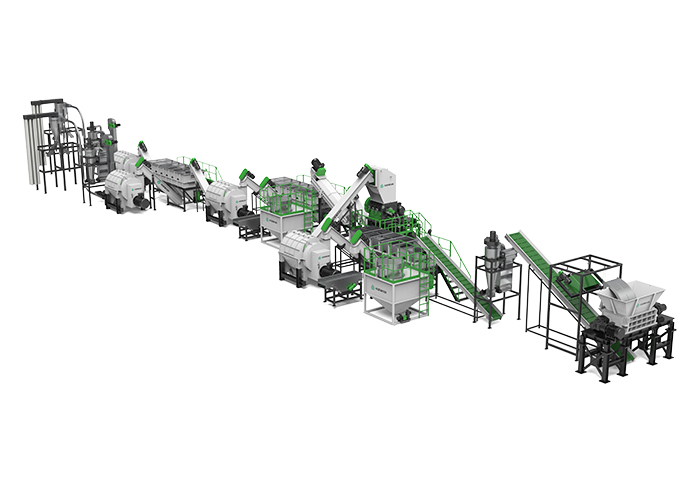

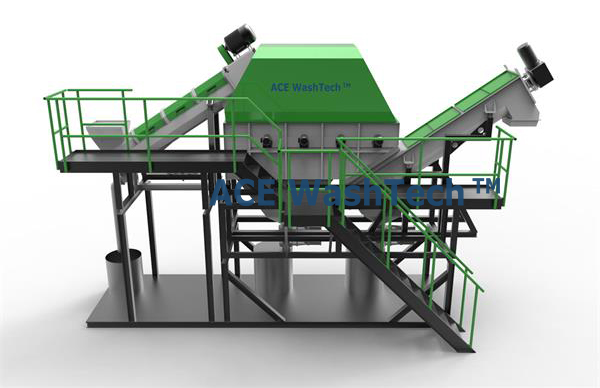

500kg/h PE PP Scraps Washing Line

- ACE WashTech

- China

- 45 days

- 100 sets

1. Multifunction combines washing and dewatering , less-labor cost;

2. Applied to rigid plastic recycling.

3. Higher output and lower energy consumption;

4. Lower investment cost for a high quality and durable machine;

5. Special design according to customer requirement.

6. Consistently quick and careful service in pro-sales and after-sales process.

7. Fast machine delivery and installation.

500kg/h PE PP Scraps Washing Line

INTRODUCTION

PP PE scraps washing line is specifically used to process PP PE hard plastic, such as PE bottles, boxs, injection molding, etc. This washing line can efficiency removed labels, dust, dirt, sands, iron, etc.

Feeding units

High throughput;

Build-in hydraulic ram;

variable faster ram movement;

Less space occupied than traditional shredders with horizontal rams;

Enclosed cutting chamber to prevent materials flying out;

Screen plates are made of wear-resistant steel, quick and easy maintenance.

Belt conveyor (Heavy duty)

Reducer type: Gear Reducer Motor, China top quality

built in sturdy frame construction in heavy duty version

side walls to avoid spilling of the feeding material

Screw loader

Label remover

Optional shredder and crusher

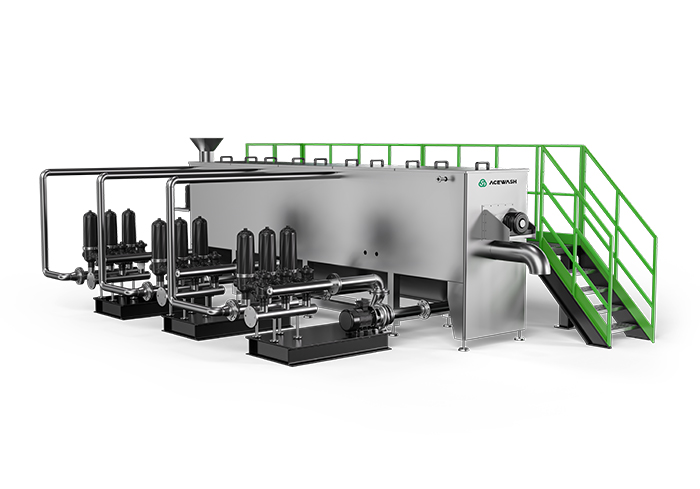

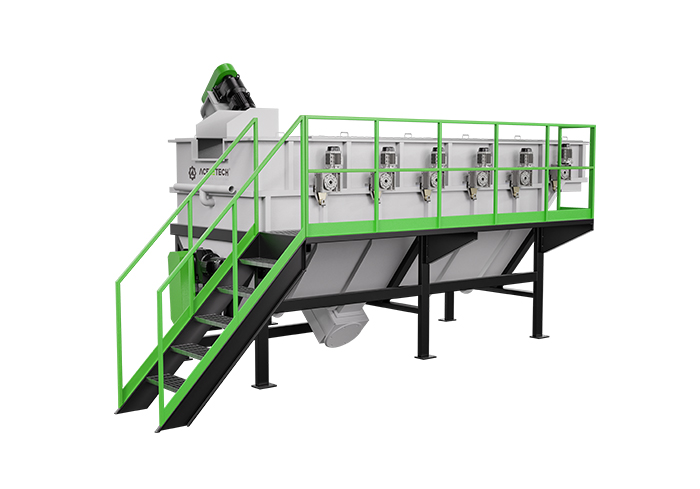

Washing units

Low water consumption, 95% recycled-release;

Simple water treatment;

High-quality separation;

Pre-sorting material( steel, sands);

Active material washing;

Automatic cleaning function;

Water recycling system online;

Intelligent control system;

Heavy material separator( double-valve control with collection tank);

Modular design and intergrated installation;

Easy exchange of elements;

Heavy duty washing, separation of different specific densities material;

Longer lifetime of downstream machines;

Dust separation devices.

Pre-washing machine

High-speed friction washer

Friction washer

Floating tank

Hot water washer

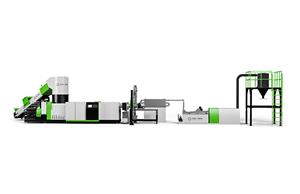

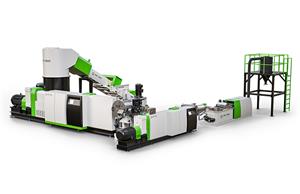

Dewatering units

Combines a cleaning centrifuge and thermomechanical drying in a single plant. This enables a clean, dry process that is easy on the material and produces consistently high end product quality;

Drying and cleaning in a single step;

Simple operations, low maintenance effort;

Automatic machine control;

Final moisture less than 7%.

Squzzer

Dewatering machine and pipeline dryer

Intelligent control system

Auto control system;

Auto warming system;

Control module system;

Data monitoring and analysis.

Final products

Clean scraps with moisture less than 7%

TECHNICAL SPECIFICATION

| Model | ECO 300 | PRO 300 | ECO 500 | PRO 500 | ECO 750 | PRO 750 | ECO 2000 | PRO 2000 |

| Capacity for rigid | 440-700kg/h | 440-700 kg/h | 900-1100 kg/h | 900-1100 kg/h | 1500-2000 kg/h | 1500-2000 kg/h | 3600-4400 kg/h | 3600-4400 kg/h |

| Installed power | 163 KW | 167 KW | 215 KW | 223 KW | 168 KW | 362 KW | 744 KW | 910 KW |

| Working power | 114 KW | 121 KW | 161 KW | 167 KW | 126 KW | 271 KW | 560 KW | 700 KW |

| Fresh water consumption | 0.5-1 m3/h | 0.5-1.5 m3/h | 0.5-2 m3/h | 1-2.5m3/h | 3-5 m3/h | 3-5m3/h | 8-10 m3/h | 8-10 m3/h |

| Moisture of output | <7% | <7% | <7% | <7% | <7% | <7% | <7% | <7% |

| Operation staff | 3 | 3 | 3 | 3 | 4-5 | 5-6 | 5-6 | 5-6 |

| Dimension (L*W*H)M | 18*4*8 | 20*4*8 | 22*4*8 | 36*4*8 | 47*4*8 | 58*5.5*8 | 74*6.5*8 | 83*6.5*8 |